Pre 1950 Properties

If your property was built pre 1950 then it’s construction is different to modern day methods, it is most likely that your property was constructed using a soft clay brick, lime mortar and a lime plaster / render finish. The wall construction will be a solid wall without an air cavity. This construction method can only be supported using traditional lime products as it needs to breath to prevent a build up of moisture and subsequent damp.

Why does a wall need to breath

Simplistically air is a gas that carries moisture, when it meets a cold surface it is unable to support the moisture it carries and condenses producing moisture droplets. The temperature at which the air condenses is known as the dew point. Between the inner face and outer face of a solid brick wall is the temperature required to create the dewpoint. Because air is a gas it can penetrate building material and within the brick if the dew point is reached moisture droplets will form, lime mortar and plaster allow these moisture droplets to evaporate into the atmosphere and prevent moisture build up producing damp, modern building products trap in the moisture creating damp and destroying the substrate.

!! Using modern Portland Cement or gypsum products will slowly destroy the buildings material structure! !!

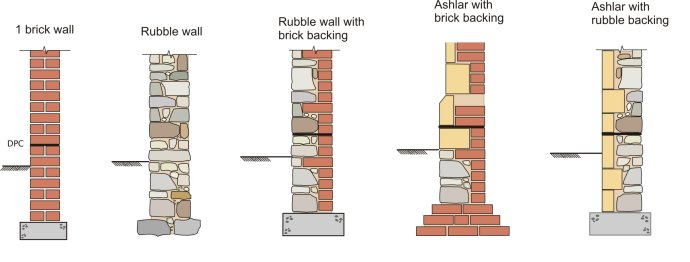

Solid Wall Construction

Modern Day Construction

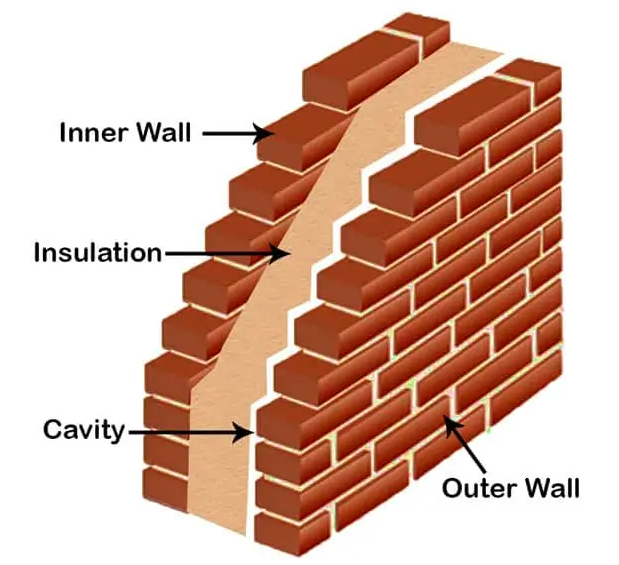

Properties built to todays standards have an air cavity that is now filled with an insulation to prevent the transfer of heat to the outside walls

The Typical modern cavity wall, insulated to prevent the transfer of heat from the inner leaf to the outer leaf.

- Damp Prevention :- Cavity walls prevent dampness in the building by removing the penetration of moisture from outer leaf to inner leaf

- Thermal insulation:- Cavity walls are great for thermal insulation in buildings due to the air present in the cavity. The acts as a non conductor of thermal heat and minimises the heat transfer from the external face of the outer leaf to the inner leaf.

What is Lime

In the context of building conservation, the term is most commonly applied to types of binder used in plaster, limewash, render and mortar that are made by burning limestone or chalk to make quicklime and then slaking this with water.

Mortar is the stuff between the bricks or blocks of stone in masonry walls which closes the gaps and makes the structure wind-proof. It is usually composed of washed sand and other aggregates, with a binder to protect it from erosion by the wind and rain. In some areas of the country, coatings of the same material as the mortar are commonly applied over the stone or brick to form a coarse, exterior plaster known as render or, in Scotland, harling. This is often finished with lime wash (lime mixed with tallow or linseed oil), coloured with natural earth pigments which produce delightfully soft, uneven colours.

Prior to the introduction of cement in the early 19th century, the binder used in mortar and render was almost invariably lime, and this material continued to be used widely until the end of the century.

What is Lime Plaster

Lime plaster is an internal wall finish that has been used for thousands of years and is still in use today thanks to its many benefits, although gypsum-based plasters and cement plasters are now often used in its place. Lime plaster is a traditional type of mortar used to cover the surface of internal walls and ceilings before painting. Records of it being used date back 140 centuries to northern Jordan.

It is made up of a mixture of lime, sand and water — sometimes fibres such as animal hair are added to strengthen the mix and to ensure a good bind with the substructure.

The lime for the plaster is a product of limestone, chalk or seashells formed from calcium carbonate that have been burnt to produce quick lime.

There are two main types of lime:

- Non-hydraulic lime is made from pure limestone and is available as lime putty. It offers brilliant flexibility and breathability.

- Hydraulic lime is produced from limestone with natural impurities containing some setting agents — it comes in powder form and begins to set once it comes into contact with water

How Do I Identify Lime Plaster?

If you live in a house that was built before 1919 it is likely to have been plastered using lime — although just because your house may have been built later than this it doesn’t mean lime won’t have been used.

Lime plaster is usually an off-white colour (as opposed to pinkish as with gypsum-based mixes.)

When trying to identify your plaster type, check for the presence of sand and hair — both tend to be good indicators of lime plaster, as is the finish being soft to the touch and obviously old.

If you have lath and plaster, cob or solid masonry walls it will be likely that lime plaster has been used.

Why Use Lime Plaster?

There are many advantages of lime plaster and although it has largely been superseded by modern gypsum-based plasters, more and more renovators and owners of period properties are realising its importance — although even those building new homes are cottoning on to its benefits.

It prevents damp. Lime plaster is a ‘breathable material’, meaning air can pass through it, unlike denser cement, or polymer-based renders and plasters. This means that when moisture forms it can escape — so no damp issues to worry about. One of the biggest causes of damp in old properties is the use of modern, impermeable materials.

It is an eco-friendly option. As well as requiring less energy to produce than many other types of modern plaster, lime also has the ability to absorb carbon dioxide from the atmosphere.

It can improve air quality. Lime plaster acts a bit like a natural dehumidifier, removing moisture from the air when needed and releasing it back when the air gets too dry.

It is very long-lasting. Because it is made of such tiny particles, lime plaster is able to penetrate deep into even tiny gaps forming a tight bond. What’s more, lime plaster actually becomes stronger over time as calcite crystals form.

It is flexible. Lime is a really forgiving material and is less likely to crack than more brittle cement-like materials.

It is very attractive. Lime plaster has a beautiful, soft natural finish that is really quite unique — it can be used in rustic and contemporary properties alike.

Is Lime Plaster Expensive?

It is generally more expensive to plaster your house using lime plaster than with cement or gypsum plaster.

There are a couple of reasons for this. Firstly, the process of applying the lime plaster takes longer and is more involved meaning higher labour costs, although most plasterers will still just charge a standard day rate.

The second reason is that lime products tend to be more expensive to buy than cement.

Your final costs will also depend on the type of lime plaster you use.

Is Lime Plaster Better Than Gypsum Plaster?

Don’t confuse gypsum plaster with cement plaster. It is made with partially or completely dehydrated gypsum (a mineral) and is usually combined with added hardeners — it is now the most commonly used type of plaster in homes.

Although often thought of as a modern material, gypsum was actually being used in the 16th century where it was often added to lime. In fact, it is still sometimes added to lime in an effort to speed up setting times, although this is largely viewed as unnecessary.

Compared to gypsum plaster lime plaster is far more breathable, allowing moisture to escape and evaporate, as well as actually drawing moisture out of the house. For this reason it is far more suitable for old buildings with solid walls, as they can retain a large amount of water which will result in damp problems when a non-breathable substance is applied.

Lime plaster is more flexible than gypsum plaster too, so is less likely to crack should movement occur. On the downside, lime plaster takes longer to set than gypsum.

How Does Lime Plaster Compare With Cement Plaster?

Cement plaster is a mixture of sand, cement and water. Although it is used as an internal finish, it is not as easy to get a smooth surface with cement plaster as with gypsum so sometimes a gypsum plaster will be applied on top.

Compared to cement plaster, lime plaster is again more breathable, flexible and eco friendly. It is also a better thermal insulator and provides an excellent bind with the wall.

On the other hand, cement plaster will set quicker and tends to be a cheaper option, both in terms of purchasing the materials and the labour required.

Lime plaster is usually applied using a three coat system that involves building up thin layers over time, allowing each to set before the next is applied.

The first layer is the ‘scratch coat’. This is a layer of around 10mm and is applied to the substrate, such as lath or exposed masonry. It consists of coarse aggregate which is scratched to give a rough finish that offers a good key for the next coat. This layer usually takes 10 days to set but can take more.

The second coat is called the ‘float coat’. It is also made using coarse aggregate and is 10mm thick, but is smoothed flatter and only scratched lightly to give a key for the final coat. This coat also takes around 10 days to set.

The finish coat – or ‘skim coat’ – is just 4mm thick. It is made with a smooth aggregate for a decorative end result. It takes around four days to set.

If you are using a lime-based plaster, there are products on the market that have been designed to reduce the labour involved and can mean the initial base coat is unnecessary.

How Long Does Lime Plaster Take to Set?

Lime plaster is usually applied using a three coat system and each coat must be left to dry out before the next can be applied — although the initial ‘scratch coat’ should only take around 10 days to set, it can take up to three or four weeks in some conditions.

The next coat usually takes another 10 days to set and the final coat around four days.

What Paint Can I Use on Lime Plaster?

It is pointless plastering your walls with beautiful, natural and breathable lime plaster only to cover them with a non-breathable paint.

For this reason it is important to use a paint suitable for use over lime plaster and also to wait as long as is recommended by your plasterer before painting. Earthborn Paints suggest that every 5mm thickness of lime needs a minimum of four weeks to cure before being painted or lime washed.

Lime wash is a very traditional way to finish lime plaster and is used not only to add colour but also to protect the wall beneath. It has microporous, alkaline properties that can deter algae growth and many conservation specialists recommend it.

On the downside, lime wash is quite maintenance heavy — it is applied by being built up in multiple layers and may also require re-application every couple of years.

An alternative is to opt for a breathable paint. These come in a wider range of colours than lime wash too.

Opting for a paint with a very matt finish is a great idea and looks very in keeping with the surface of lime plaster.

Stay in touch: